Classification of titanium and top ten performance( 0.5 mm titanium sheet)

time2021/10/27

- Classification of titanium and top ten performance( 0.5 mm titanium sheet),Classification of titanium and top ten performance.

Classification of titanium (Titanium tube size metioned:1.375 id titanium tube,2.5 inch titanium tube,4 inch titanium pipe,10mm titanium tube)

Industrial pure titanium: The impurity content of industrial pure titanium is more than that of chemical pure titanium, so its strength and hardness are slightly higher. Its mechanical and chemical properties are similar to those of stainless steel. Compared with titanium alloy, pure titanium has better strength and has better oxidation resistance. It is better than austenitic stainless steel, but has poor heat resistance. TA1, TA2, and TA3 increase in impurity content, mechanical strength and hardness increase in order, but plastic toughness decreases in order.

β-type titanium: β-type titanium alloy can be strengthened by heat treatment, with high alloy strength, good weldability and pressure workability, but its performance is unstable and the melting process is complicated.

A, β titanium plate: 0.5-4.0mm

B. Glasses plate (pure titanium): 0.8-8.0mm

C. Standard plate (pure titanium): 1 x 2m Thickness: 0.5-20mm

D. Plate for electroplating and other industries (pure titanium): 0.1-50mm

Uses: electronics, chemicals, watches, glasses, jewelry, sporting goods, mechanical equipment, electroplating equipment, environmental protection equipment, golf and precision processing industries.

Titanium tube specifications: φ6-φ120mm wall thickness: 0.3-3.0mm

Titanium tube uses: environmental protection equipment, cooling pipes, titanium heating pipes, electroplating equipment, rings and various precision electrical appliances pipes and other industries.

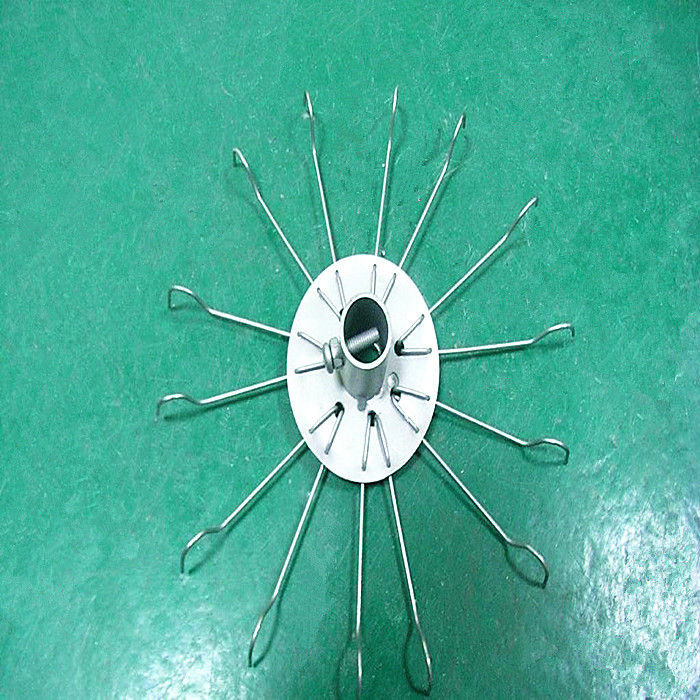

A,β titanium wire specifications: φ0.8-φ6.0mm

C,Titanium wire specifications: φ0.2-φ8.0mm hanger dedicated

Titanium wire use: military industry, medical, sporting goods, glasses, earrings, headwear, electroplating hangers, welding wire and other industries.

A. Square bar specifications: square bar: 8-12mm

B. Polished round bar: φ4-φ60mm

C. Wool rod, black leather rod: φ6-φ120mm

Titanium rod use: mainly used in mechanical equipment, electroplating equipment, medical, various precision parts and other industries.

Top ten performance

1,Low density, high specific strength

The density of titanium metal is 4.51g/cm3, which is higher than aluminum and lower than steel, copper, and nickel, but its specific strength is at the top of the metal.

2,Corrosion resistance

Titanium is a very active metal, its equilibrium potential is very low, and the thermodynamic corrosion tendency in the medium is high. But in fact, titanium is very stable in many media. For example, titanium is corrosion-resistant in oxidizing, neutral and weakly reducing media. This is because titanium and oxygen have a great affinity. In the air or in an oxygen-containing medium, a dense, strong adhesion and inert oxide film is formed on the surface of titanium, which protects the titanium matrix from corrosion. Even due to mechanical wear, it will quickly heal itself or regenerate. This indicates that titanium is a metal with a strong tendency to passivation. The titanium oxide film always maintains this characteristic when the medium temperature is below 315℃.

In order to improve the corrosion resistance of titanium, surface treatment technologies such as oxidation, electroplating, plasma spraying, ion nitriding, ion implantation and laser treatment have been developed to enhance the protection of the titanium oxide film and obtain the desired corrosion resistance. Effect. In response to the need for metal materials in the production of sulfuric acid, hydrochloric acid, methylamine solution, high-temperature wet chlorine, and high-temperature chloride, a series of corrosion-resistant titanium alloys such as titanium-molybdenum, titanium-palladium, and titanium-molybdenum-nickel have been developed. Titanium castings are made of titanium-32 molybdenum alloy, titanium-0.3 molybdenum-0.8 nickel alloy is used in environments where crevice corrosion or pitting corrosion is common, or titanium-0.2 palladium alloy is used locally in titanium equipment, and they are all well used. Effect.

3,Good heat resistance

The new titanium alloy can be used for a long time at a temperature of 600°C or higher.

4,Good low temperature resistance

Titanium alloy TA7 (Ti-5Al-2.5Sn), TC4 (Ti-6Al-4V) and Ti-2.5Zr-1.5Mo are represented by low-temperature titanium alloys. Its strength increases with the decrease of temperature, but the plastic change is not Big. It maintains good ductility and toughness at low temperatures of -196-253°C, avoids cold brittleness of metals, and is an ideal material for cryogenic containers, storage boxes and other equipment.

5,Strong anti-damping performance

After metal titanium is subjected to mechanical vibration and electrical vibration, its vibration decay time is the longest compared with steel and copper metal. This performance of titanium can be used as a tuning fork, medical ultrasonic pulverizer vibrating element and high-end acoustic speaker vibrating film, etc.

6,non-magnetic, non-toxic

Titanium is a non-magnetic metal and will not be magnetized in a large magnetic field. It is non-toxic and has good compatibility with human tissues and blood, so it is adopted by the medical profession.

7,the tensile strength is close to its yield strength

This property of titanium shows that its yield ratio (tensile strength/yield strength) is high, which means that the plastic deformation of metal titanium material is poor during forming. Due to the large ratio of the yield limit of titanium to the modulus of elasticity, the resilience of titanium during molding is large.

8,Good heat transfer performance

Although the thermal conductivity of metallic titanium is lower than that of carbon steel and copper, due to the excellent corrosion resistance of titanium, the wall thickness can be greatly reduced, and the heat exchange method between the surface and the steam is dropwise condensation, which reduces the heat group. It can also reduce the thermal resistance without scaling, so that the heat exchange performance of titanium is significantly improved.

9,low modulus of elasticity

The elastic modulus of titanium is 106.4GPa at room temperature, which is 57% of steel.

10,Inspiratory performance

Titanium is a chemically very active metal, which can react with many elements and compounds at high temperatures. Titanium getter mainly refers to the reaction with carbon, hydrogen, nitrogen, and oxygen at high temperatures.