The inner wall of the medical titanium alloy slender tube is polished, and the roughness can reach below Ra0.1!-capillary action

time2022/03/29

- Surface tension and capillary action.Why does not water come when we make hole in capillary tube?

Titanium alloys have the advantages of high strength, sufficient toughness, light weight, and not easy to oxidize, etc., and have become the main raw materials for implants or devices in orthopaedics, dentistry and cardiovascular. Among many titanium alloy medical devices, polishing the inner wall of the slender titanium alloy tube is the most difficult. Before, only a Japanese company could achieve the inner wall roughness below Ra0.08μm, which can be said to be a world-class Titanium alloys have the advantages of high strength, sufficient toughness, light weight, and not easy to oxidize, etc., and have become the main raw materials for implants or devices in orthopaedics, dentistry and cardiovascular. Among many titanium alloy medical devices, polishing the inner wall of the slender titanium alloy tube is the most difficult. Before, only a Japanese company could achieve the inner wall roughness below Ra0.08μm, which can be said to be a world-class problem.With the continuous deepening of research on microporous polishing in recent years, there is a solution for polishing the inner wall of titanium capillaries.

Of course, polishing the inner wall of titanium alloy capillary is not only a process of polishing, but a systematic project. The inner hole roughness of domestic stainless steel pipes wants to reach Ra0.08, instead of products from Japan or other countries, but have you considered the production process, materials, and roughness of the bottom blank before polishing? Even the best craftsmanship also needs the connection between craftsmanship and craftsmanship! The Great Leap Forward is the Great Retreat!

When the slender tube has a good bottom embryo, we will use the special machine for polishing Smack micro-holes to polish it, and it is very easy to reach below Ra0.1. Smack Abrasive Flow has successfully done several cases of inner hole polishing of titanium alloy slender tubes. Let's first look at the effect before and after polishing.

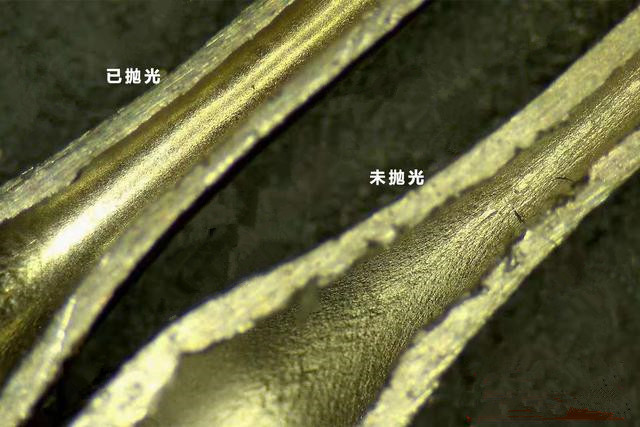

Here is the effect at the transition from a large hole to a small hole:

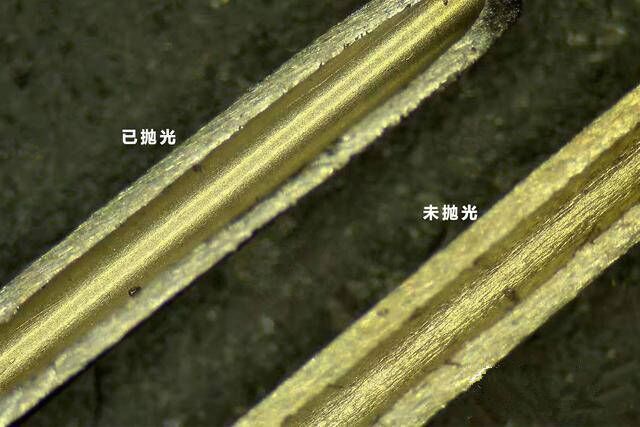

This is the effect of the small hole end:

It can be seen from the pictures under the microscope that the inner wall of the unpolished tube has very obvious lines, one small vertical bar and one small vertical bar. After polishing the inner wall, the texture is gone, and the texture of the inner wall becomes very delicate. Polishing is not as simple as brightening, but reducing roughness, otherwise we can solve it by soaking in polishing liquid. For the inner wall of the capillary, electrochemical polishing does not reduce the roughness. Physical grinding must be used, and general mechanical polishing simply cannot reduce roughness while maintaining accuracy. Smack abrasive flow adopts special fluid abrasive, which squeezes the abrasive into the inner hole of the capillary.

Fluid polishing does not generate instantaneous local high energy and high pressure, but continuously grinds in a soft and rigid manner (the actual speed is also very fast), so it will not produce elastic and plastic deformation on the surface of the workpiece, and will not form thermal stress, residual stress, cold Surface defects such as hardening can not only maintain but also enhance the quality characteristics of the inner wall of titanium alloys. For the polished titanium alloy thin tube, a brightening process can be added, which is relatively simple and will not be discussed again.