Astmb365 Tantalum wire in coil with high melting point and low vapor pressure

- group name

- Tantalum Wires

- Min Order

- 1 kilogram

- brand name

- MMR Parts Processing | Custom Parts Manufacturing

- Nearest port for product export

- shanghai, tianjin, xi'an

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, Westem Union, Cash

- update time

- Sun, 28 Dec 2025 12:06:31 GMT

Paramtents

Grade R05200, R05400

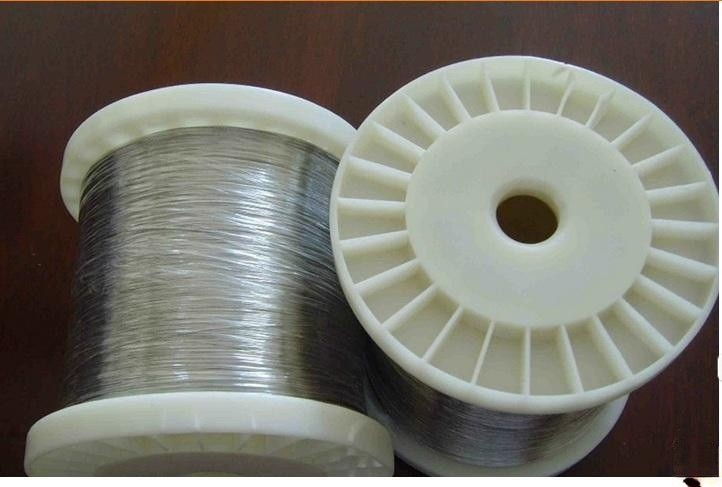

Diameter 0.1mm - 4mm

Standard ASTMB365,ASTM F560

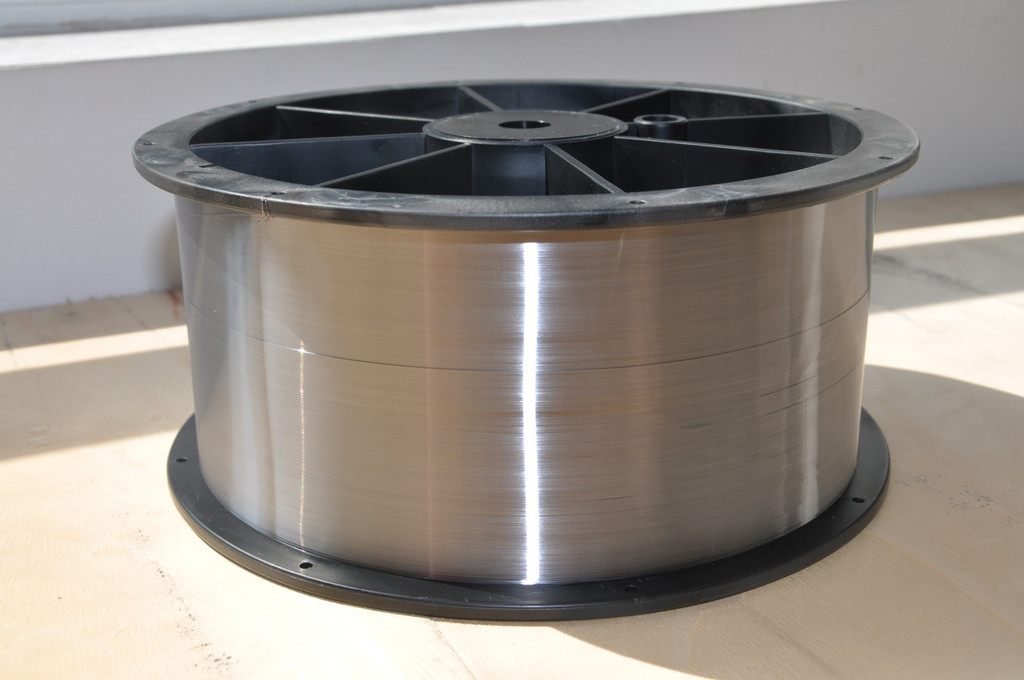

Shape Shape: Straight, Coil

Condition Hard, Semi-hard, Mild

Surface polished surface,black surface

Specifications Industrial,Aerospace,Medical

Packging & Delivery

-

Min Order1 kilogram

Briefing

Our tantalum wire drawing price is really good,and tantalum wire uses in many field, and our tantalum welding wire is hot sell.

Detailed

AS a tantalum wire supplier ,all of our tantalum wire have been strictly inspected and the quality is guaranteed. We provide tantalum wire mesh polished with treatment and cutting tantalum bar services . The following are detail informations about our tantalum materials.

|

Grade |

R05200, R05400 |

||

Standard | ASTMB365,ASTM F560 | ||

|

Diamter |

0.1mm - 4mm |

||

|

Shape |

Coil, straight |

||

|

Condition |

Hard, Semi-hard, Mild

|

||

|

Surface |

Polished surface, Black surface |

||

|

Specifications |

Aerospace, Medical, Industrial

|

||

Chemical composition

|

Element

|

C | O | N | H | F | Mo | Nb | Ni |

Si

|

Ti

|

W

|

|

RO5200(% Max)

|

0.01 | 0.015 | 0.01 | 0.0015 | 0.01 | 0.02 | 0.1 | 0.01 |

0.005

|

0.001

|

0.05

|

|

RO5400(% Max)

|

0.01 | 0.03 | 0.01 | 0.0015 | 0.01 | 0.02 | 0.1 | 0.01 |

0.005

|

0.001

|

0.05

|

Tolerance (mm)

Diamater | Tolerance |

0.1~0.2 | ±0.005 |

0.3~0.5 | ±0.007 |

0.6~0.7 | ±0.010 |

|

0.8~1.5

|

±0.015

|

|

1.6~2.0

|

±0.020

|

|

2.1~3.0

|

±0.030

|

3.1~4.0 | ±0.040 |

Testing :

Chemical composition test,

Physical properties test,

Appearance defects inspection,

Ultrasonic flaw detection.

Application :

TElectron-beam melting,

Laboratory equipment,

Substitute for platinum,

Manufacturing super alloys,

Glass and ceramic industries,

Metallurgical,

Machinery processing,

Sputtering targets,

Aviation, aerospace industry,

Medical equipment, etc.

Features :

High melting point, low vapor pressure,

Good cold working performance,

High chemical stability, strong resistance to liquid metal corrosion,

Large dielectric constant of the surface oxide film.

What we can do for you?

- If the above model is not suitable for your workpiece, please tell us your need and then we can send you the most satisfying drawing.

- contact us