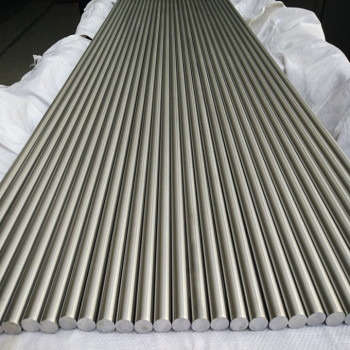

High quality 6242 titanium bar bar by forging processing for aircraft engine compressor parts and aircraft skin materials

- group name

- Titanium Round Bars

- Min Order

- 1 kilogram

- brand name

- MMR Parts Processing | Custom Parts Manufacturing

- Nearest port for product export

- shanghai, tianjin, xi'an

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, Westem Union, Cash

- update time

- Sun, 28 Dec 2025 13:48:04 GMT

Paramtents

Grade Ti-6AL-2Sn-4Zr-2Mo-0.1Si

Diameter 6mm - 300 mm

Length ≤6000mm

Technology Hot-Rolled, Hot forging , Machining

Condition Cold rolled(Y), Hot rolled(R), Annealed (M)

Surface Pickling surface, Polished surface, Black surface

Specifications Aerospace, Medical, Industrial

Packging & Delivery

-

Min Order1 kilogram

Briefing

Detailed

Chemical composition, weight percent (%) | |||||||||||||||

Grade |

C ≤ |

O ≤ | N ≤ |

H ≤ |

Fe ≤ | Al | Sn |

Zr |

Si | Ni | Mo | Other Elements Max. each | Other Elements Max. total | ||

Ti6242 | 0.05 | 0.15 | 0.05 | 0.0125 | 0.25 | 5.5~6.5 | 1.8~2.2 | 3.6~4.4 | ≤0.13 | — | 1.8~2.2 | 0.1 | 0.3 | ||

Grade | Physical properties | ||||||

|

Tensile strength Min |

Yield strength (0.2%, offset) |

Elongation in 50mm Min (%) |

|||||

ksi | MPa | Min | Max | ||||

ksi | MPa | ksi | MPa | ||||

Gr5 | 130 | 895 | 120 | 825 | — | — | 10 |

Diameter | tolerance | ||

Hot forging bar | Hot rolling bar | Cold rolling bar | |

6~15 | ±1.0 | ±0.60 | ±0.30 |

16~25 | ±1.5 | ±0.70 | ±0.40 |

26~40 | ±2.0 | ±1.0 | ±0.50 |

|

41~60

|

±2.5

|

±1.5

|

±0.60

|

|

61~90

|

±3.0

|

±2.0

|

±0.80

|

|

91~120

|

±3.5

|

±2.2

|

±1.20

|

121~160 | ±5.0 | — | ±1.80 |

|

160~200

|

±6.5

|

—

|

±2.00

|

201~230 | ±7.0 | — | ±2.50 |

- If the above model is not suitable for your workpiece, please tell us your need and then we can send you the most satisfying drawing.

- contact us