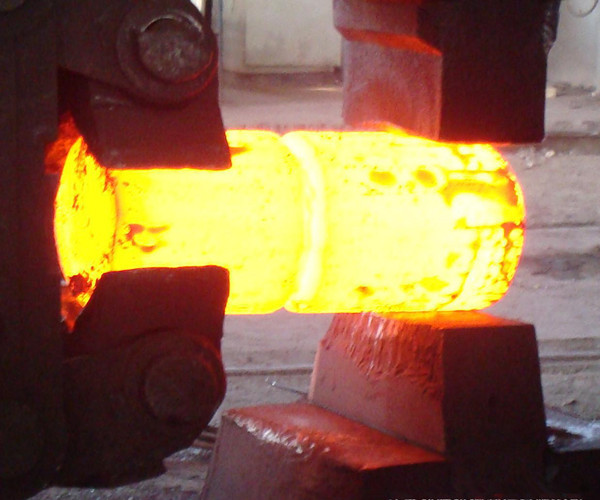

What are the forging methods of titanium alloy? And how to make titanium forge?

publisherandy

time2021/10/19

- The main methods used in titanium alloy forging are: free forging, open die forging (with burrs, die forging), closed die forging (without burrs), extrusion die forging, multi-direction die forging, partial die forging, isothermal die forging,

Titanium forging products we always do like: titaniaum block,titanium ring and titanium disc.

The main methods used in titanium alloy forging are: free forging, open die forging (with burrs, die forging), closed die forging (without burrs), extrusion die forging, multi-direction die forging, partial die forging, isothermal die forging, its characteristics are as follows:

(1) Free forging. Free forging is generally performed between two flat or die without cavity. The tool used in free forging has simple shape, high flexibility, short manufacturing cycle and low cost. However, the labor intensity is large, the operation is difficult, the productivity is low, the quality of forging is not high, the processing allowance is large. Therefore, it is only suitable for the performance of the product has no special requirements, and a few cases. For large forgings, free forging is mainly used as a breaking process.The free forging process can forge the blank into stepped bar material, or make the bad material into simple shapes such as round cake or rectangle by sensitive rough or flattening method.

(2) open die forging (with burr die forging). The blank deforms between two modules with cavities, the forgings are confined inside the cavities, and excess metal flows out of a narrow slit between the two molds, forming burrs around the forgings. Under the resistance of the die and the surrounding burrs, the metal is forced into the shape of the cavity.

(3) Closed die forging (no burrs die forging). During closed die forging, no transverse burrs are formed perpendicular to the direction of die movement. The die cavity of a closed die has two functions: one part is used for shaping the wool and the other part is used for guiding.

(4) extrusion forging. Using extrusion die forging, there are two kinds of extrusion die forging and reverse extrusion die forging. All kinds of hollow and solid parts can be made by extrusion die forging. Geometric precision can be obtained,etc.Forgings with higher degree and denser internal structure.

(5) multi-direction die forging. On the multidirectional die forging machine. In addition to the vertical punching plunger, there are two horizontal plungers, its ejector can also be used for punching, the ejector pressure than ordinary hydraulic press ejector pressure is greater. In multidirectional die forging, the slider alternately and jointly acts on the workpiece from both vertical and horizontal directions, and one or more punch holes are used to make the metal flow outward from the center of the die cavity to achieve the purpose of filling the die cavity.There are no burrs of ordinary forgings on the parting lines of simple parts.

(6) Partial die forging. In order to forge large integral die forging parts on the existing hydraulic press, sectional die forging, pad die forging and other partial die forging methods can be used. The characteristic of partial die forging method is to process the forgings one section at a time, so the required equipment tonnage can be very small.Generally speaking, this method can be used to process large forgings on medium-sized hydraulic presses.