What are the main factors affecting the service life of titanium anodes?

time2021/12/08

- What are the main factors affecting the service life of titanium anodes?

1. Current density: The current density is inversely proportional to the anode life. The higher the current, the shorter the anode life.

2. Titanium base material: The base material of the anode is generally pure titanium, and the material is required to be above TA1. If the purity of the base material used is not enough, the corrosion resistance will be greatly reduced, which will have a great impact on the service life of the anode.

3. Electrolyte: It is forbidden to contain fluoride ions, cyano ions and sulfide ions in the electrolyte. If there is, it will have a greater impact on the life of the anode.

4. Inverted pole: Inverted pole is a way often used in anode repair, which can make the passivated old coating fall off the surface of the substrate. Therefore, it is prohibited to reach the pole during use.

5. Frequent power failures: In the absence of current, the coating will be greatly damaged if it is soaked in the solution for a long time.

6. Man-made damage: There should be no hard scratches on the anode surface. If part of the coating is damaged, even a small scratch will cause the anode to be corroded and passivated quickly and eventually lead to failure.

7. Short circuit: It is forbidden to contact the anode and cathode when the power is on. The instantaneous current caused by the short circuit is very large, which can burn the electrode plate.

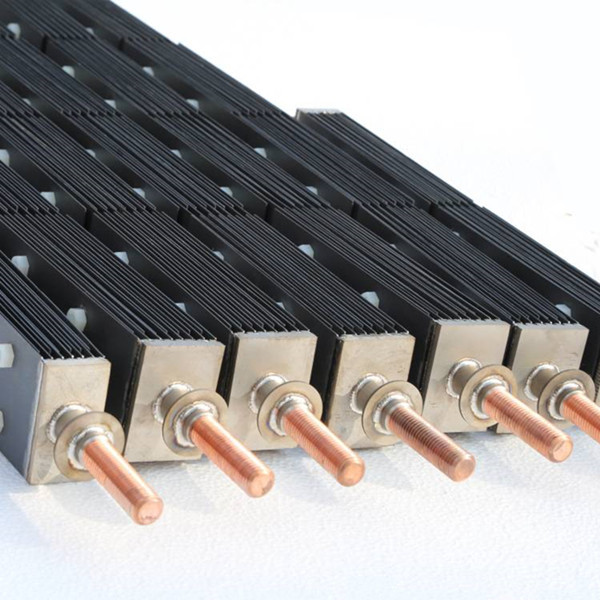

We often see titanium anode,such as:platinum coated titanium anode(platinized titanium anode).titanium anode basket(titanium anode basket for electroplating).